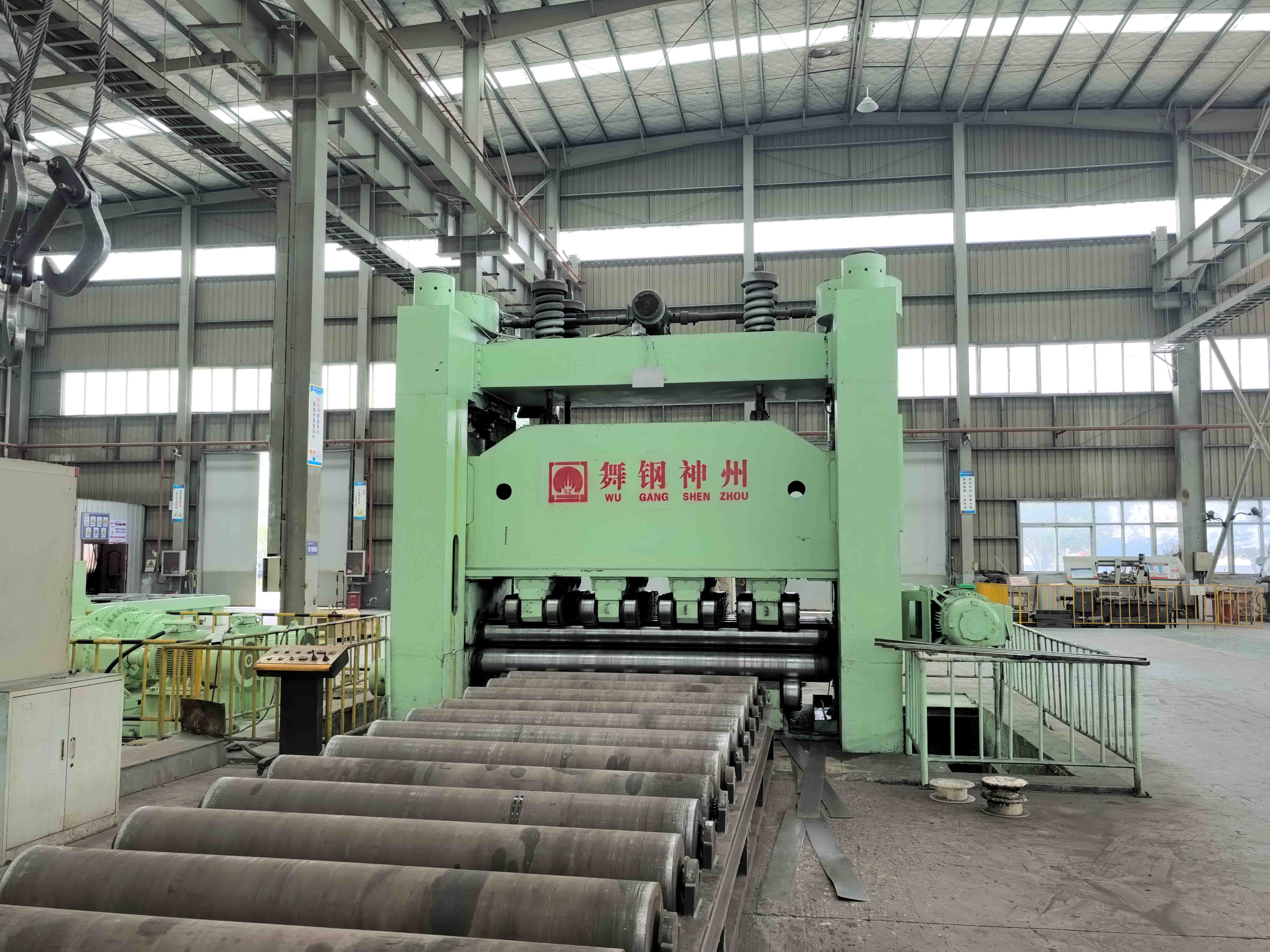

The company has a specialized and modern metal composite material production line, which is in a leading position in the industry. The

main production equipment includes 2 fully automatic plasma welding machines (P+T), 19 cranes, 3 roller leveling machines, and 1 fully

controlled oil press machine. The leveling width can reach 5000mm and the thickness can be 2-300mm. The company also has 3 American

Haibao fully CNC plasma cutting machines, 3 fully controlled heat treatment furnaces, 2 automatic flipping machines, 9 automatic polishing

machines, and 1 milling machine (12M), which can heat treat tube plates, cylinder plates, and head plates of various material combinations,

effectively solving the problem of heat treatment furnace matching and shortening the waiting time for heat treatment; Welding, grinding,

cutting, milling, lifting and other equipment are also CNC equipment, which is a powerful guarantee to ensure customer delivery time.